Pretreatment: The choice of pretreatment process depends on various factors: material, geometry.

In this area, as general contractors, we cover the entire range of systems with our partner:

Pre-treatment methods:

- Power wash with blow-off zone

Robot-guided cleaning methods:

- Cleaning

- Surface cleaning with ROBCLEAN 800®

- Flame treatment

CO2 cleaning:

The CO2 snow jet cleaning process allows dry, environmentally friendly, residue-free cleaning of sensitive areas.

By using a high-speed cleaning jet, maximum cleaning performance can be achieved with minimal CO2 consumption.

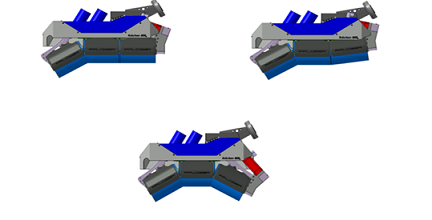

- Surface cleaning with ROBCLEAN 800®

Before a workpiece is painted, it must first be cleaned. The entire workpiece is cleaned fully automatically with robots using special brushes.

The infeed can be parameterized continuously in the program using the robot controller. Thanks to the concave and convex infeed of the brushes, even demanding areas can be cleaned in a targeted manner and cycle times optimized. With the reversibility of the cleaning direction, effective utilization of the cycle time is also guaranteed

The outer brush elements are infinitely adjustable. This ensures constant contact with the surface to be cleaned.

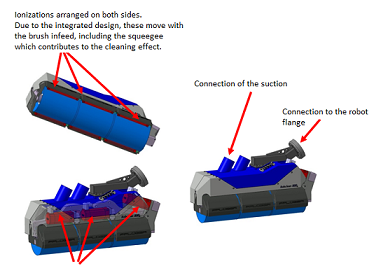

Ionizations are arranged on both sides. Due to the integrated design, these move with the brush infeed, including the squeegee which contributes to the cleaning effect.

Painting Booth Technology

Painting booths with dry and wet paint separation

Dry separation:

Spray booths with dry separation: With dry separation, the exhaust air is cleaned using different filters.

Wet separation (Venturi principle):

With wet separation, there is a larger amount of water in the suction duct for the exhaust air, which is constantly moved and filtered. The exhaust airflow is now passed through the water-laden separator. By reducing the pipe cross-section, the exhaust air is accelerated in such a way that the water and spray mistake intensively mixed.

Small parts paint booth

Large parts of the paint booth

Robot and application technology:

- Air atomizing spray guns

- High-Speed rotary atomizer

- Airless spray guns

Painting of Large Parts – Painting of Trailers

DRYERS

CONVENTIONAL PAINT DRYERS

External coating (tunnel), heater group, air circulation and exhaust technology, exhaust system and ventilation systems.

One could also mention TNV or RNV, if you offer that.

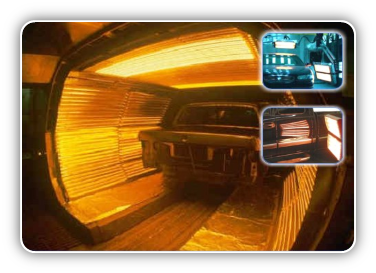

IR Dryer

The infrared system can be used for drying or as a hot air oven in a variety of ways. The convector speed is very fast and the efficiency is very high so that considerable cost savings can be achieved when drying or cooking (duct systems).

The infrared system can be used for drying, and also as a hot air oven with the exhaust air heat in a variety of ways. The heating rate of the irradiated parts is very fast and the efficiency is very high so that considerable cost savings can be achieved during drying.

The exhaust air heat can then be used further via duct systems with heat exchangers.